And sports cars don't always catapult off the ground. The operation on a sports car is a catapult start, but the average family car will just burn out the clutch. Some people like the push of the start or want to get off the ground quickly, they will take the throttle to release the clutch. This indicates that the clutch is not fully disengaged. When the pedal is depressed all the way, the transfer is hard with a bang.

#Clutch burn out free

In the driving school's training field, you can often smell the burning smell because the training is semi-linkage operation.ģ. When the disc burns out, you will find that the pedal free travel has increased. The semi-linkage also makes the clutch pressure plate unable to make the flywheel and friction plate closely fit, resulting in a difference in speed.

#Clutch burn out drivers

Many novice drivers of manual transmission models will put their feet directly on the clutch pedal after the operation of clutch, which may lead to the clutch can not be pressed, so that the flywheel and friction plate have relative movement, resulting in the clutch plate burned out.Ģ, long time semi-linkage. Starting with several Toyota transmissions (U660, A750 and A760), these frictions will also find its way into some Ford and GM units as well.1. The fluid flow dynamics with this new plate’s unique groove patterns and friction materials (figure 8), is expected to positively impact durability, performance and clutch drag reduction. This newly added HT plate emerged from continued studies they originally conducted with groove designs to see what impact it had on durability and performance with the GPX plate. In fact they have announced a new friction they call the HT plate which is totally different in material and grooving. This tends to provide cooler operating temperatures and endurance of this clutch pack which is especially suited to the demands placed on this particular assembly. It is very compatible to Honda fluid and due to its unique friction material and special grooved patterns. Honda clutches and fluid are a must with the exception of Raybestos’ GPX® friction plates (figure 7). Bushing tool kits are available in the aftermarket to remove and replace shaft bushings. After inspecting the vehicle, we found the clutch master cylinder leaking, the clutch pedal excessively high and the clutch was slipping. Companies like Slauson Transmission parts recondition these cases so that bearing pocket wear is a thing of the past.

When rebuilding this transmission it is imperative to restore shaft alignment along with shaft bushing and tube wear otherwise repeat failure is imminent. The third clutches are being applied (albeit briefly) during high rpm conditions with less pressure control resulting in clutch burn out with rotational damage.

After 80k miles or so when shaft alignment begins to be compromised, this forced 4-2 downshift becomes a problem. The purpose of this brief pulse of the clutch is to assist in a smooth shift transition.

#Clutch burn out manuals

Factory manuals show this clutch being pulsed on and off during an engagement from Park to Drive without mentioning the 4-2 shift strategy. It is understandable how the third clutch can burn out due to a pressure loss caused by worn feed pipe bushings, but the rotational damage? Jesse Zacarias of Elec-Tran discovered a computer strategy which briefly pulses the third clutches on and off during a forced 4-2 downshift. In fact one symptom this causes that rebuilder Max Deese in Chicago experienced is a sudden stall while waiting at a stop light. When this happens to the main shaft, the rings to cut into the regulator valve body compromising converter pressure. The wear caused by shaft side play not only damages feed pipe sealing capabilities dropping clutch pressure (4 th & 5 th clutch main shaft, 3 rd clutch counter shaft, 2 nd clutch secondary shaft), damage can also extend to the sealing rings on the front of the main shaft. Stationary hydraulic feed pipes in the end cover that fit into these shafts run hard against the rotating bushings inside the shafts (figure 6). Overtime, vibration combined with torque causes these bearings to wear into the case allowing for unwanted shaft side play. The main shaft, counter shaft and secondary shafts are each supported by their own bearings secured in the main case cover (figure 5).

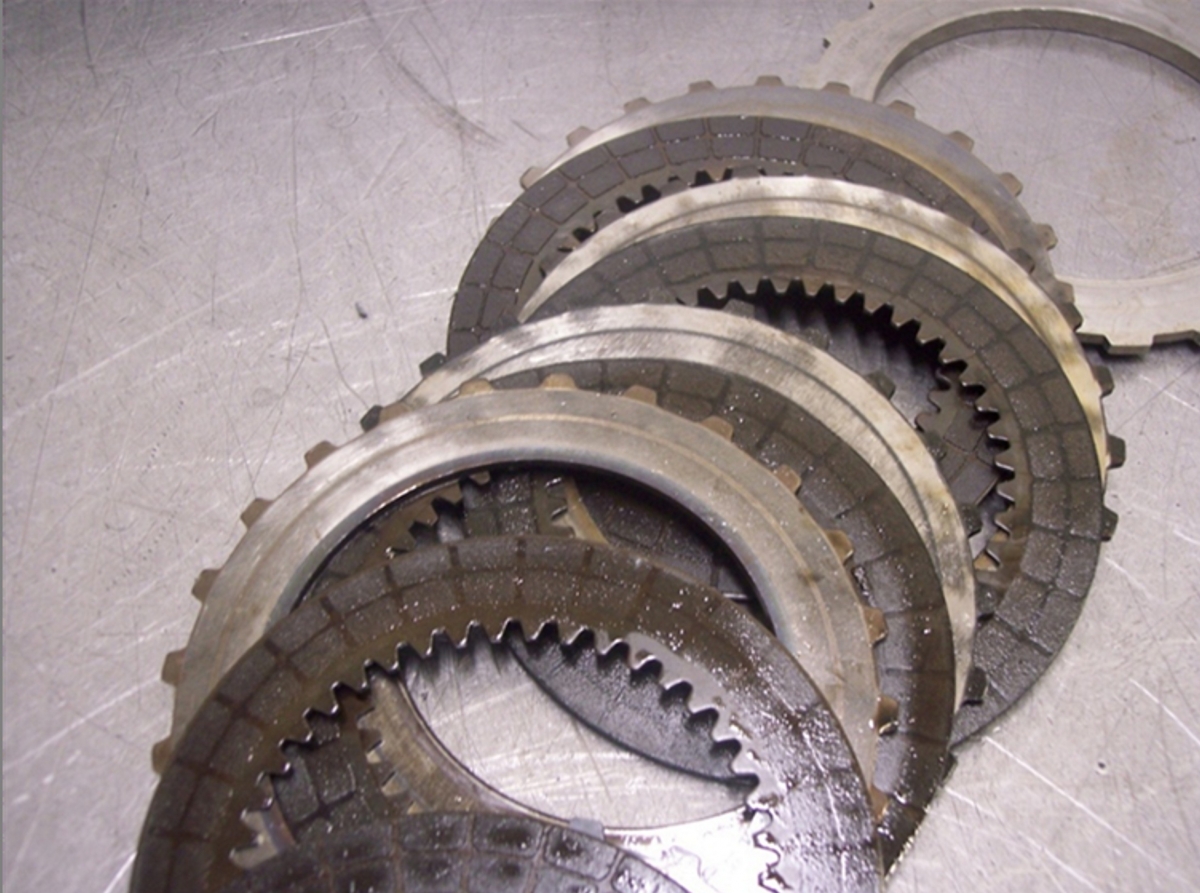

Many times rotational damage of the piston, return spring and spring retainer accompanies the third clutch burn out (figures 2, 3 and 4). It is not unusual for a 2000-2004 Honda or Acura vehicle using a 5 speed 3 shaft style automatic transmission to come in to the shop with the third clutches destroyed (figure 1).

0 kommentar(er)

0 kommentar(er)